Cable assembly M5, M8, M12-connector

Cable assembly M5, M8, M12-connector

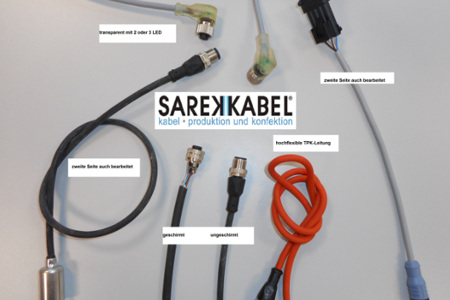

Do you know the feeling? You need a good sensor cable with overmoulded M12 connector in any coding – and you can get this from various suppliers. But unfortunately the M12 remains on one side, since on the other side you need another plug. Or you need a specific assembly on one side and an M12 on the other side. Or the unthinkable: a specific cable as opposed to the supplier standard!

The solution: starting from small MOQ SAREK KABEL will produce a customized M12 lead – YOUR M12-assembly. Or an M12-cordset with a special cable from SAREK, or a cable provided by you: M12 customized assemblies from SAREK!

Click on the image to enlarge

In addition to overmolded M8 and M12 connectors, we can of course also mount freely assembled M8 and M12 connectors on unshielded and shielded cables. This is recommended for small series, for application-specific cables and also for spiral cables:

Connection cable for handheld scanner with hollow socket for power supply, M12 connector for the scanner and D-Sub on the device. Custom spiralized.

Of course, the specialists at Sarek Kabel also mount the assembled sensor cables on or in devices or assemblies

You can find other molded connectors here

Power to the system: Schuko plug mounted on M12 power socket. On request, from a small minimum quantity, the Schuko plug can also be molded onto the M12 cable.

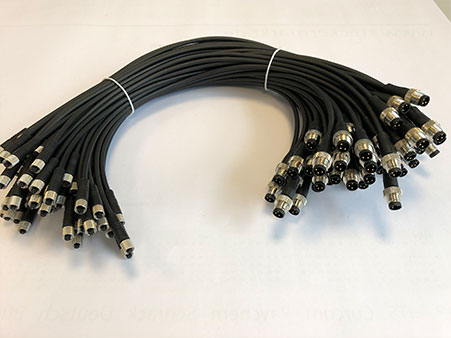

Shorten and strip Grundfos sensor cable to required lengths, attach wrap label, attach 1542897 shielded 4p M8 A-cod.

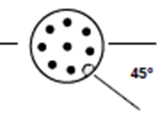

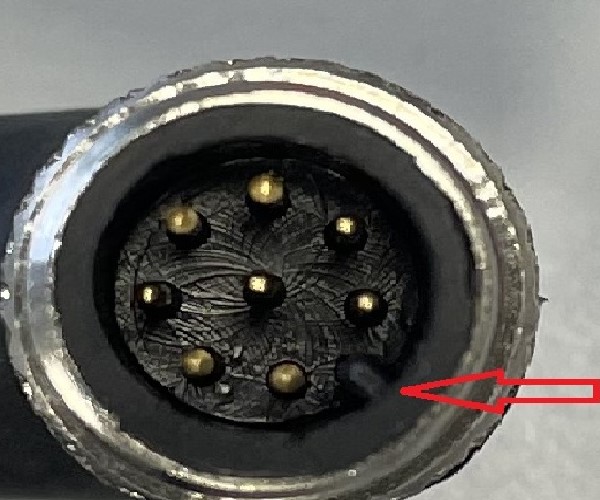

Coding position

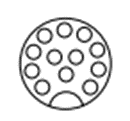

For the different connector sizes there are different codings for different applications. Basically, these are represented in the mating face via latching lugs or contours, as shown in DIN EN 61076. Shape and position are defined, thus the positioning of the individual pins is also defined. Depending on the application, the position of the coding may be required at a different location, which means that the positioning of the individual pins is shifted for the same assignment.

Case study for an extension cable:

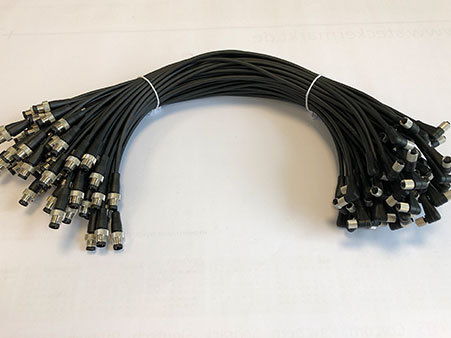

CAT.5 Industrial Ethernet 4x2xAWG26 with 2 x M12 right angle male to female, each A-coded according to DIN EN 610762-101.

Also with the small M8 plugs the coding position can be changed, also here naturally particularly with the angle plugs interesting as installation assistance. Here a 4-pole female connector. These are round in the standard, the coding is therefore the round plug face circumference. On the example, this was offset by 180 degrees - installation made easy without twisting the connection cable.