Task

A hot runner moulding tool for plastic injection molding needs thermocouples for temperature measurment and power supply for the heating elements. The existing, expensive, standard cable is to be replaced by a less expensive alternative with more compact dimensions. We conducted such an analysis of the real application requirements: as a result we found that many of the properties that the expensive standard cable possessed were actually not required by the customer.

Technical challenge

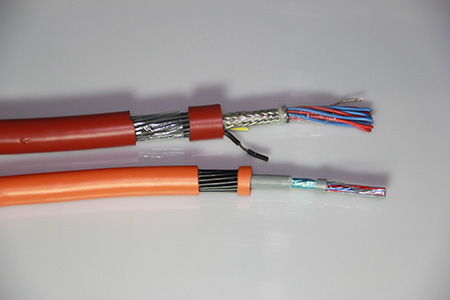

In order to protect the measuring signals the thermocouples needed to be shielded. Also the cable must have sufficient flexibility to facilitate the occasional tool change. Finally due to the industrial environment the cable jacket must be mechanically more stable than the previous silicone jacket.

Solution

The conductor cross-section of the thermocouples and the supply cores are adapted to the real requirements. Insulation and jacket materials are adjusted to the application temperature. As an outer jacket we used the mechanically very resistant and abrasion resistant polyether-PUR in signal color orange. As a result of the modifications to the cable we obtained weight savings of 25%, a reduced diameter of 18% and a cost reduction of 21%.